Submit your analysis with recommendations to answer the following questions:

Which of the routing alternatives would you recommend to meet the initial 90-day deadline for the 25-bus shipment? Why? Train or waterway? To which port(s)? What would it cost?

Case 14.1 Nürnberg Augsburg Maschinenwerke (N.A.M.)

The Nürnberg Augsburg Maschinenwerke, one of Germany’s most successful manufacturing companies, enjoys a long tradition. It dates from 1748, when the St. Antony Iron Mill opened in Oberhausen (located in the heart of the Ruhrgebiet industrial region) during the beginning years of German industrialization. The owners soon founded additional iron and coal mills, then established the firm as Gute Hoffungshuette (GHH). Shortly following, in Augsburg and Nürnberg, several companies joined together to form Nürnberg Augsburg Maschinenwerke (N.A.M.). These two firms, GHH and N.A.M., would ultimately merge in the early twentieth century.

In the interim, N.A.M. had distinguished itself through the work of Rudolf Diesel, who invented his famous engine and then brought it to N.A.M. late in the nineteenth century. The diesel engine competed with the internal combustion engine in early automotive design and today powers heavy trucks, turbines, railroad engines, and ships. Based on this success, N.A.M. swiftly expanded manufacturing operations and distribution across the globe, only to have its foreign operations compromised by international politics on two occasions. First, N.A.M. lost most of its foreign property in the wake of World War I, a setback that, among other adjustments, encouraged its merger with GHH in 1920. Second, N.A.M. lost all of its foreign property again after World War II and had to rebuild and restructure much of its domestic operation as well. In 1955, the company opened a truck unit in Munich, which would later become the new company headquarters.

By 2003 the company had reclaimed its preeminence as a global player in heavy truck and bus design, engineering, and manufacturing, as well as in print technology, rocket, and energy science. It had reestablished both its plants and sales offices across the globe, and is one of the largest diesel engine makers in the world. Karl Huber was the N.A.M. regional vice president of sales for South America, and he supervised a team of local sales representatives in the countries of that continent, plus a small group of people in the Munich headquarters.

On August 15, Huber received an e-mail from Leopold Escabar in Caracas, who had just returned from an important meeting with local authorities in charge of redesigning the local public transportation systems for the Brazilian cities of São Paulo and Rio de Janeiro. Escabar had attended the meeting along with salespeople from competing truck and bus companies. Escabar gave Huber some good news and some bad news. Escabar had been told N.A.M. was favored to receive an order for 224 N.A.M. class #4-G two-section articulated buses (or “accordion” buses, as Escabar liked to call them), with the possibility of securing a contract for an additional 568 buses. To win the business, however, N.A.M. would have to meet cost and timing guarantees.

The customers first required that N.A.M. must match or beat the total price per unit, including shipping, that N.A.M. had received for a shipment of 233 buses to the transit district of Buenos Aires, 6 months earlier. That price was 124,500 € per bus. Huber had built in a small extra profit margin on the Buenos Aires deal, so he felt confident that to meet their pricing demand he could shave profit a little, if necessary, in this case.

The second guarantee, however, was more worrisome: The Brazilian authorities were feeling political heat because they were badly behind schedule in implementing their transportation plan and needed proof to show the public that their new programs were underway. So they had made this offer to N.A.M. on the strict condition that the company could ensure delivery of the first 25 buses to Santos, the port that serves São Paulo, by November 15 (only 3 months away). If N.A.M. delivered this initial 90-day order on time, the company would receive a contract for the remaining 199 vehicles to be delivered in full within the following 15 months. The follow-on order for 568 more vehicles was, essentially, contingent on meeting terms of the initial contract to the letter, with regard to the 224 buses. All buses were to be delivered to the Port of Santos.

Huber whistled softly to himself as he read Escabar’s e-mail. This would be a major order. In a single stroke, it could move him ahead of his regional sales targets for several quarters to come. Huber immediately sent back an e-mail, instructing Escabar to tentatively accept the offer, assuring the local authorities that they’d have their 25 buses in 90 days and the rest within 18 months. N.A.M. would formally agree to the proposal within 5 working days. Then he scratched his head and tried to figure out how. Huber had 4 days before the next managing director’s meeting, at which time he would present the project and, with the vice president for production, propose a plan to accomplish it. Huber lunged for the phone and, scarcely glancing at the number pad, his fingers automatically dialed 4823.

Dieter Berndsen, the production V.P., listened as his old friend Huber described the opportunity, jotting down notes as he went. He explained to Huber that the factory in Munich was already producing to its limits, and the two other German facilities were also facing a backlog of orders through the fourth quarter. So Berndsen offered two immediate possibilities. First, he considered wait listing a 40-bus order from the Thai military at the Munich plant. He said he was reluctant to do this, however, because the Thais had ordered several product modifications, and the Munich line had already been set up to handle them. Second, Berndsen suggested sending the new Brazil order to N.A.M.’s Prague facility. Prague was the smallest of all the European plants and had the oldest, slowest assembly lines, but they were just finishing up manufacture of an order of #4-G’s and, due to a recent order cancellation, would now be working at only 70 percent capacity through year-end. Within 8 weeks, figured Berndsen, Prague could easily handle the order for Brazil’s first 25 buses.

Huber eagerly agreed, as Berndsen decided to recommend Prague for this assignment. The problem was that this facility could not produce fast enough to fulfill more than 20 percent of the rest of the contract (for the 224 buses), which meant that he would have to coordinate production and delivery on the rest of this order from other plants. Sighing audibly over the phone line, Berndsen said, “Thanks a lot for the new headache, Hubie. Let me mull this one over for a bit before I call you back. But don’t worry, we’ll make your deadline—and you will make your bonus. Just remember to cut me in for a piece.”

Huber chuckled, thanked him, and hung up.

Berndsen decided to split the full order (224 buses) among the factories in Prague and the much larger plant in Munich. To finalize both scheduling and pricing, he now needed to estimate the time it would take to fulfill the order, as well as the cost of transportation. He was inclined to use the Deutsche Bundesbahn to transport the buses by train to the North Sea port of Bremerhaven, but he wasn’t sure that this was the best solution for each of the plants involved.

Berndsen’s immediate problem was the first shipment of buses, which would be ready to leave Prague on October 15. Berndsen asked Marcus Weiss, his supply-chain analyst, to create a worksheet that would show all costs and times required to get the buses from the Prague factory to the port of Bremerhaven, and he also asked Weiss to identify viable alternatives. (Europe possesses an extensive network of rivers and channels that connect together its network of commercial waterways. In fact, the European Union champions a Motorways of the Seas concept that specifies four short-sea shipping lanes that involve its member nations.) Consequently, the Prague plant sometimes transported buses on barges via the Elbe, north to Hamburg. The German plants occasionally shipped north to Bremerhaven or Hamburg, via a network of industrial waterways, or westward, over the River Rhein, to the port of Rotterdam in the Netherlands.

Following is some of the information Weiss assembled for Berndsen:

By train, the geographic distances between plants and ports were as follows: Prague to Hamburg 490 kilometers, Prague to Rotterdam 640 kilometers.

N.A.M. would need 3 days to get the buses from the factories in Prague to the Port of Bremerhaven or Hamburg by train and 4 or 5 days to reach Rotterdam. The advantage of Rotterdam comes, however, in the shipping time from there to Santos, which saves a day versus Bremerhaven or Hamburg, and ocean shipping charges are 5 percent less.

The Czech railway could transport the load to the border with Germany, where the Deutsche Bundesbahn would take over the flatcars, which carry two buses each. The Bundesbahn quotes a price of €1,643 per flatcar from Prague to Hamburg, which includes the service by its Czech partner. If rail were used from Prague to Rotterdam, the cost per flatcar would be €1,943. In either port, it costs another €45 per bus to have it unloaded and driven to alongside the vessel. The vessel line can load and pack 20 buses per day, charging €25 per bus and up to 30 buses with overtime charges. The overtime charges would amount to an additional €15 per bus (for buses 21, 22, and so on). All charges per bus included detaching the two halves.

Using the waterways instead of trains to reach the Hamburg port from Prague would decrease the transportation cost by €48 per bus. Waterway transportation would increase the transport time necessary by 3 days to Hamburg.

For transoceanic shipping on any of these routes, N.A.M. works with Hapag-Lloyd AG. Hapag-Lloyd is able to offer a cheap and flexible commodity cost, through its alliance with other ship lines for the ocean transport of the buses. One vessel could carry up to 125 buses as deck cargo, but they would have to be disassembled at their accordion junctions and then reassembled again at their destination.

The cost per bus (in shipments of 20 buses or more) from Bremerhaven or Hamburg to Santos is quoted at €6,000, and the trip requires 18 days. Hapag-Lloyd indicates that deck space is available for the initial shipment of 25 buses on vessels departing Hamburg on October 24, October 27, October 31, and November 3. Hapag-Lloyd also has space on vessels leaving from Rotterdam to Santos on October 23, October 28, and November 2.

Handling (unloading) in Santos is estimated to cost another €94 per bus, and this includes reattaching the two halves.

The interest for N.A.M.’s line of credit is 10 percent.

Professional homework help features

Our Experience

However the complexity of your assignment, we have the right professionals to carry out your specific task. ACME homework is a company that does homework help writing services for students who need homework help. We only hire super-skilled academic experts to write your projects. Our years of experience allows us to provide students with homework writing, editing & proofreading services.

Free Features

Free revision policy

$10Free bibliography & reference

$8Free title page

$8Free formatting

$8How our professional homework help writing services work

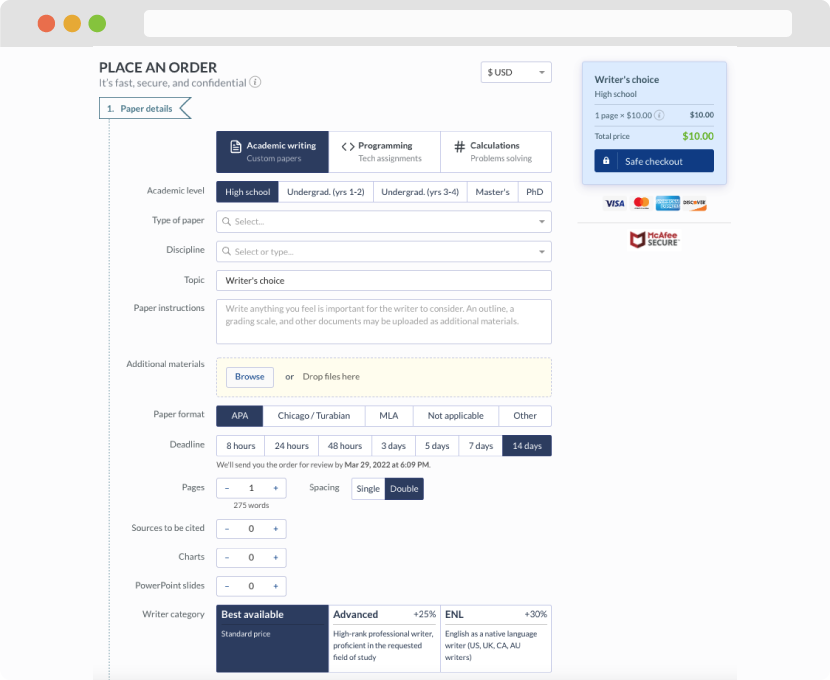

You first have to fill in an order form. In case you need any clarifications regarding the form, feel free to reach out for further guidance. To fill in the form, include basic informaion regarding your order that is topic, subject, number of pages required as well as any other relevant information that will be of help.

Complete the order form

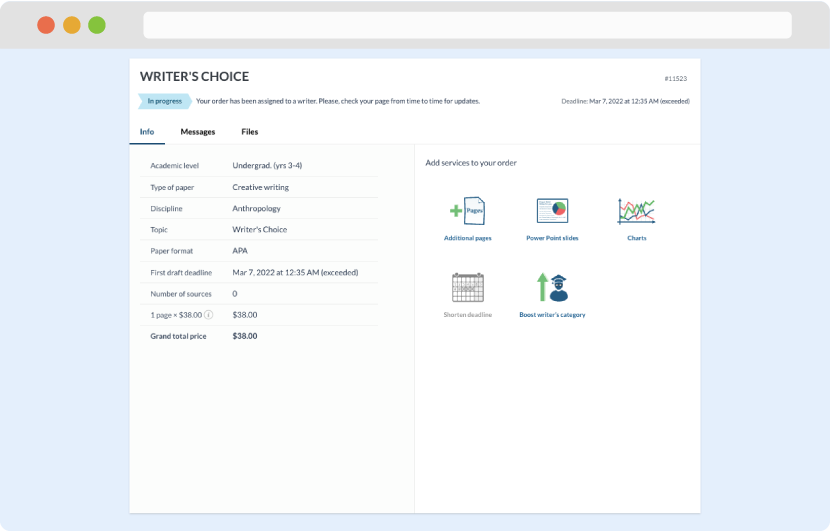

Once we have all the information and instructions that we need, we select the most suitable writer for your assignment. While everything seems to be clear, the writer, who has complete knowledge of the subject, may need clarification from you. It is at that point that you would receive a call or email from us.

Writer’s assignment

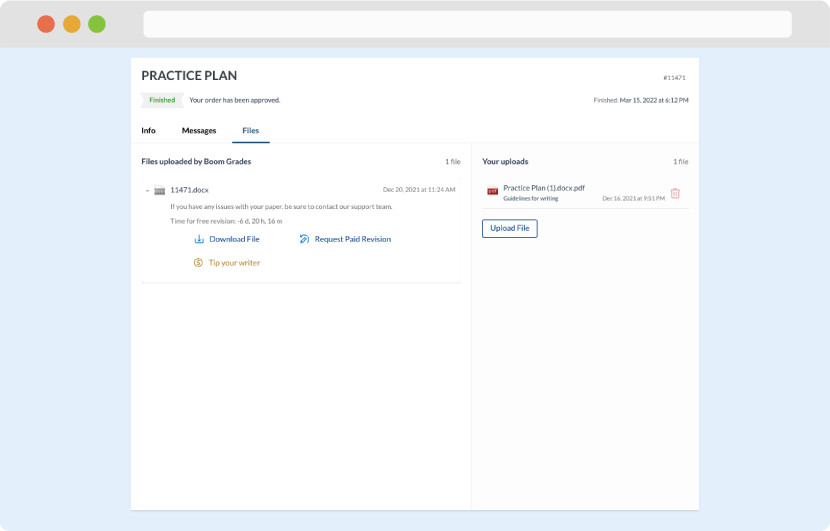

As soon as the writer has finished, it will be delivered both to the website and to your email address so that you will not miss it. If your deadline is close at hand, we will place a call to you to make sure that you receive the paper on time.

Completing the order and download